Miscellaneous

Myriad and interesting documents tied to concerns about the plant.

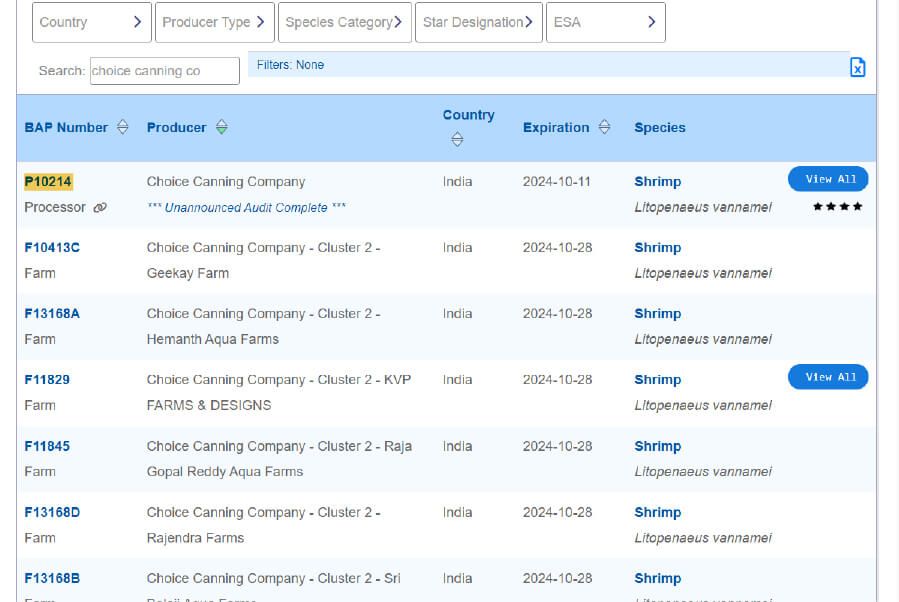

What is the status of Choice Canning’s Best Aquaculture Practices certification?

Best Aquaculture Practices (BAP) is a certification program run by the Global Seafood Alliance (GSA), an industry body that promotes responsible practices. Previously certified by BAP, Choice Canning’s Amalapuram plant (Unit III) seems to no longer have its certification.

On December 4, 2023, after a successful onsite evaluation, the Global Seafood Alliance provided Choice Canning’s Amalapuram plant (Unit III) with a BAP certification, as seen in this document.

A search of the Amalapuram plant’s facility number, P10977, on the BAP’s list of certified producers, on May 10, 2024, did not return any results. This seems to indicate the plant is no longer certified by BAP.

A search for the term, “Choice Canning” on the BAP’s list of certified producers on May 10, 2024 only returned a result for Choice Canning’s plant in Cochin, India, which has a different facility number. The search did not return any results for the Amalapuram plant (Unit III), which again seems to indicate this facility is no longer certified by BAP.

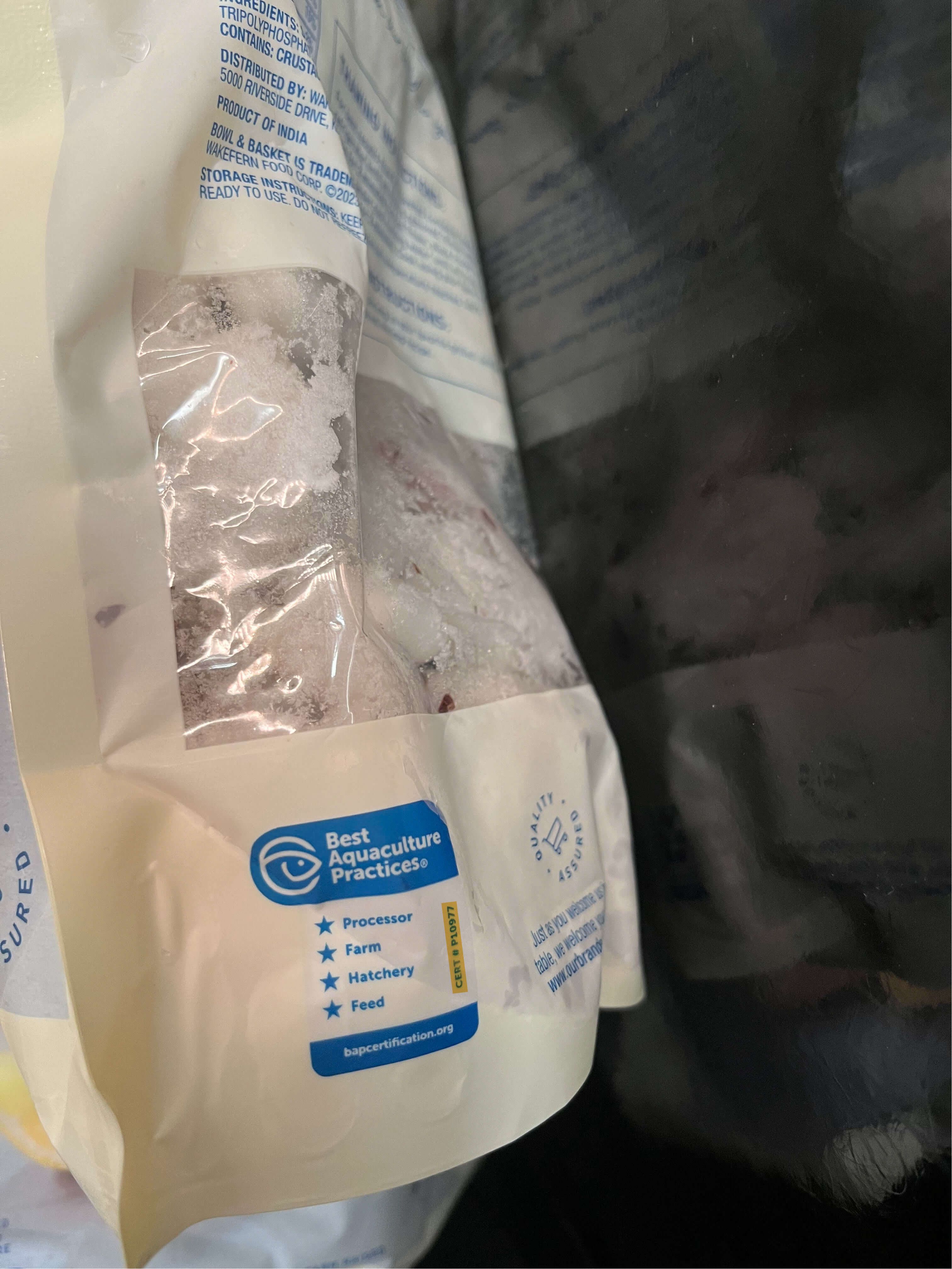

A Wakefern store in Pittston, Pennsylvania still had frozen shrimp packages from the Amalapuram plant, displaying the BAP logo, on the shelves on May 10, 2024. Reporters confirmed this shrimp came from the Amalapuram plant by looking at the certification number on the BAP logo: P10977. This photo seems to indicate that shrimp that was processed at the Amalapuram plant (Unit III) was still being sold with the BAP logo, although the facility is no longer listed as a BAP-certified producer.

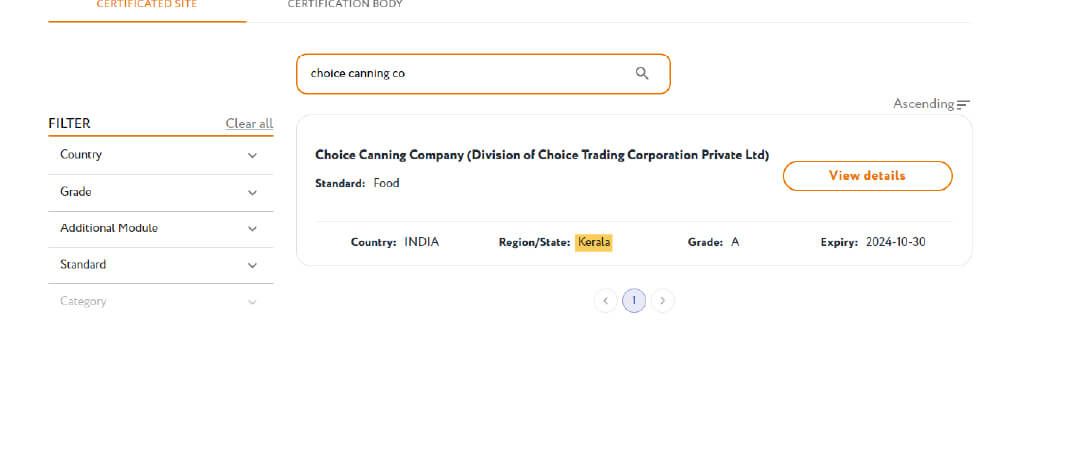

What is the status of Choice Canning’s British Retail Consortium certification?

The British Retail Consortium (BRC) is a global certification program that promotes responsible food safety standards. Previously certified by the BRC, Choice Canning’s Amalapuram plant (Unit III) seems to no longer have its certification.

On December 12, 2023, after a successful onsite evaluation, the British Retail Consortium provided Choice Canning’s Amalapuram plant (Unit III) with a food safety certification, as seen in this audit report.

A search for the term, “Choice Canning Co” in the BRC’s directory of certified sites on May 10, 2024 only returned a result for a site in the southwestern Indian state of Kerala. (The Amalapuram plant, Unit III, is located in a different state, on India’s eastern coast.) This seems to indicate that the Amalapuram plant is no longer certified by BRC.

What is the relationship between Choice Canning and the Bapatla plant that recently had a shipment stopped by the FDA?

Speaking to industry press in May 2024, a spokesperson for Choice Canning said that the company stopped leasing a factory in Bapatla, India (also called “Unit II”), at the end of September 2023, and that they did not know that the plant was still exporting shrimp in its name until the F.D.A. sent a letter about three shipments that had been blocked due to the presence of veterinary drugs.

Between September 2023 and November 2023, in a WhatsApp chat dedicated to “Bapatla Operations,” senior Choice Canning managers continued to discuss the processing and sale of shrimp from a plant in Bapatla referred to as “Unit II.” This is significant because in response to an F.D.A. import refusal for shrimp from the Bapatla plant that cited Choice Canning, the company said it “had nothing to do with the shipment,” and that it had stopped leasing the plant in September.

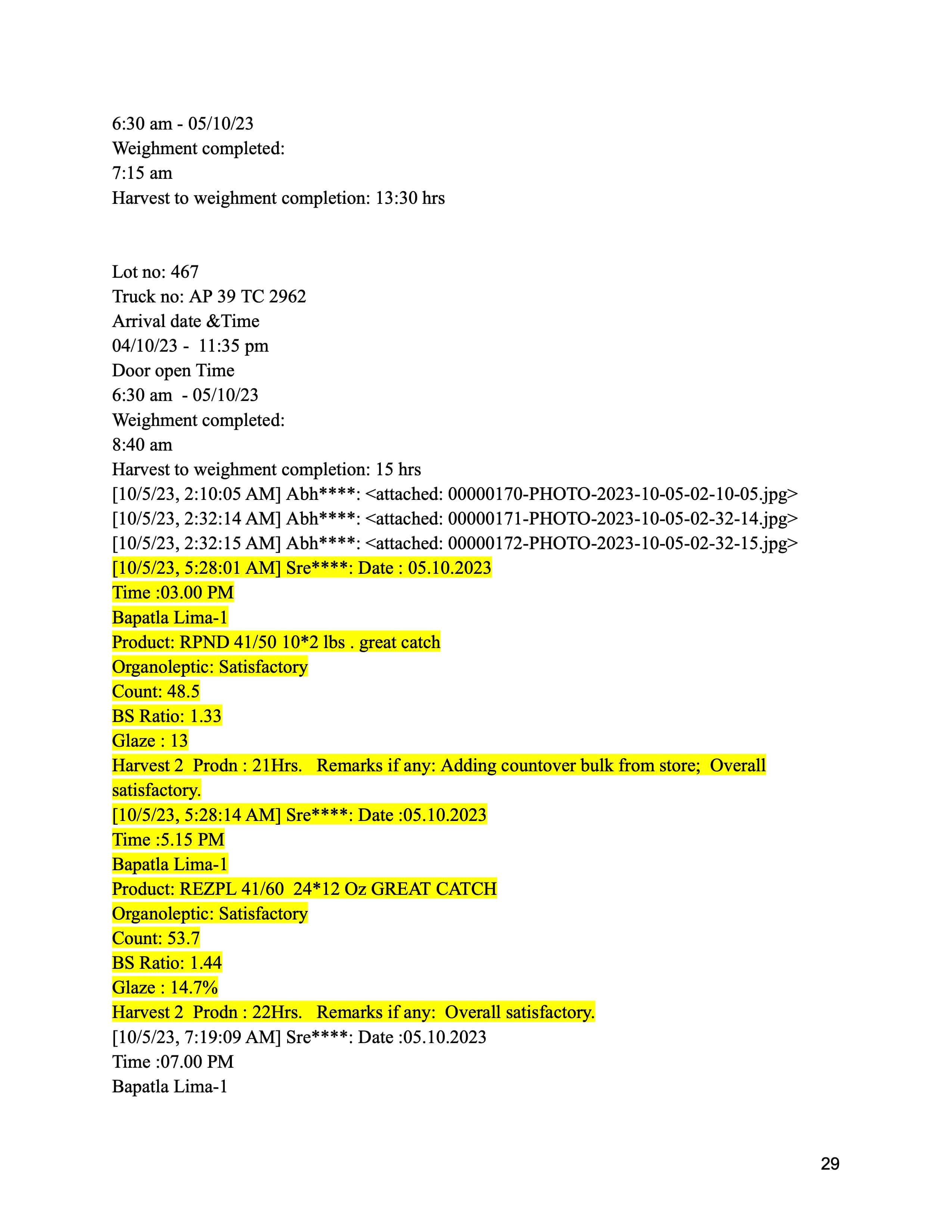

Recurring sets of notes like these throughout the WhatsApp chat kept track of ongoing production statistics at the Bapatla plant (Unit II). This seems to indicate that Choice Canning staff were involved in processing at the Bapatla plant after September 2023.

Reports in this format appeared throughout the WhatsApp chat, documenting loads of shrimp being delivered to the Bapatla plant (Unit II) for processing throughout September and October 2023. This seems to indicate that Choice Canning continued to process raw shrimp at the Bapatla plant after September, which is the month the company told the FDA they had already stopped leasing the plant.

In a voice memo sent to senior management on October 6, 2023, JT, the CEO of Choice Canning, pushed for more shrimp to get shipped out from the plant in Bapatla (Unit II). This appears to counter Choice Canning’s claim that the company stopped leasing the plant in September.

Choice Canning CEO JT asked staff to outline their plan for selling the shrimp in storage at the Bapatla factory (Unit II). Choice Canning COO Gaurav Rathore briefed JT on an upcoming trip he would be taking to check on the cold storage at the plant in Bapatla. This seems to indicate that Choice Canning staff were still involved in operations at the facility after September.

In a WhatsApp message on Oct. 9, 2023, Choice Canning CEO JT pushed staff to keep products moving out of the Bapatla factory (Unit II). This appears to show that Choice Channing was still storing some of its shrimp at the Bapatla factory after September.

In a WhatsApp message on October 12, 2023, a production executive in Kochi wrote that they planned to use some shrimp from the Bapatla plant (Unit II) to fill an order for the Amalapuram factory. This seems to indicate that Choice Canning was still filling orders using shrimp from the Bapatla plant after September.

In a WhatsApp message to staff on Nov. 6, 2023, Choice Canning CEO JT pushed staff to hit shipment goals at the Bapatla plant (Unit II). This seems to indicate that Choice Canning was still shipping shrimp from the Bapatla plant a month after the date they said they had exited their lease there.

In a voice memo sent to senior management on November 20, 2023, JT, the CEO of Choice Canning, suggested moving shrimp from the Amalapuram plant to the plant in Bapatla (Unit II) to be repackaged. This seems to indicate that some shrimp from the factory in Amalapuram was packaged and sold from the plant in Bapatla, more than a month after date Choice Canning said it had exited its lease there.

In a message on Dec. 11, 2023, Choice Canning director Thomas Jose checked in with other managers about a plan to ship shrimp from the plant in Bapatla (Unit II) to a plant in Amalapuram. This is noteworthy because it implies that Choice Canning still had shrimp at the Bapatla plant in December, even though the company said it had stopped leasing the plant in September.

In a message on Dec. 13, 2023, Choice Canning COO Gaurav Rathore pushed company managers to get shrimp moved from the plant in Bapatla (Unit II) to a plant in Amalapuram. This may demonstrate that Choice Canning was still using shrimp from the Bapatla plant to fulfill orders in December, despite the company's claim that it had stopped leasing the factory in September.

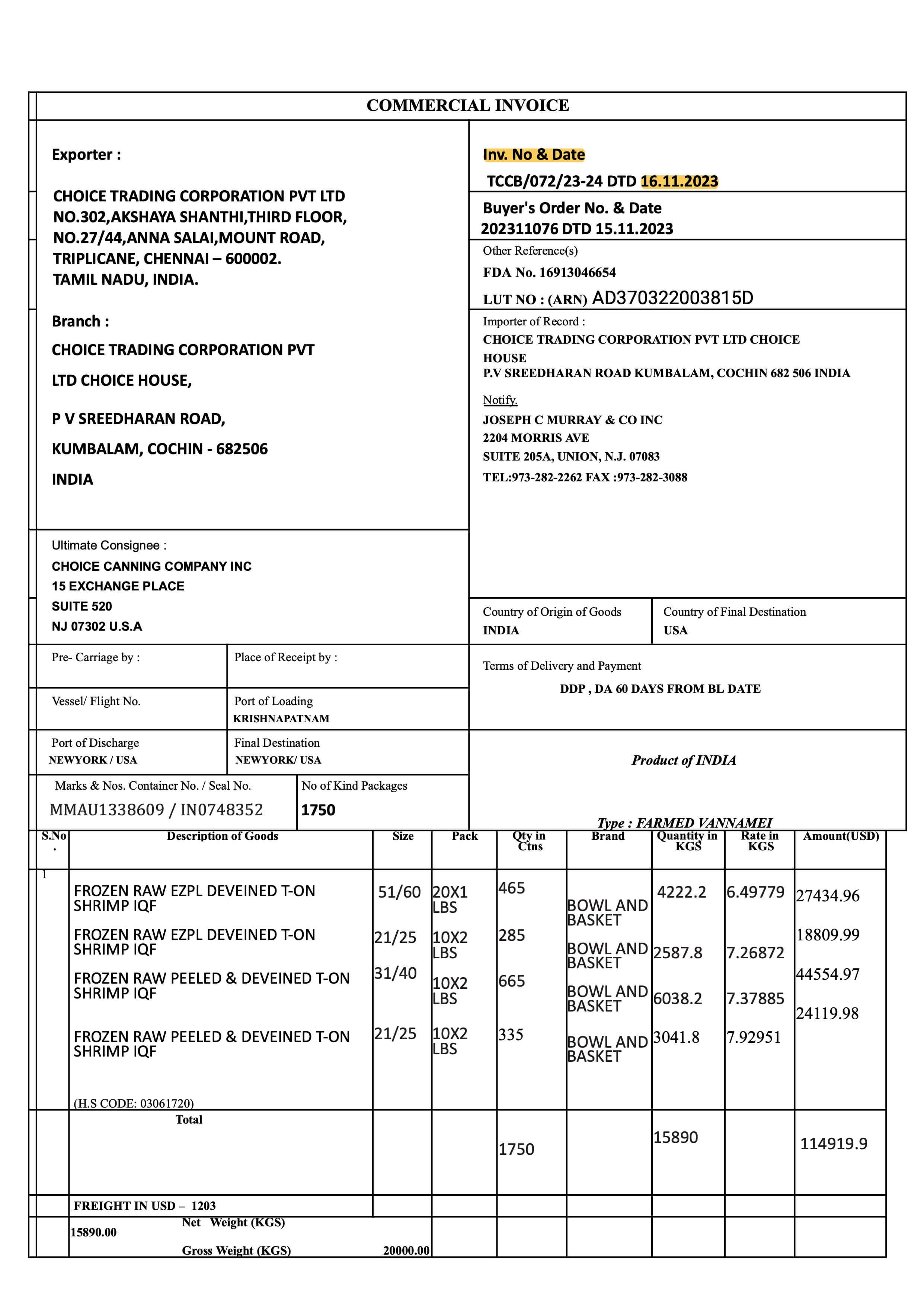

In email exchanges and WhatsApp messages between November 2023 and January 2024, Choice Canning staff reviewed invoices, tracking logs, and product inventory for shrimp at a factory in Bapatla (Unit II), which Choice Canning claims it did not use after September 2023.

In an email exchange between Choice Canning staff in November 2023, managers discussed purchase orders. An invoice was attached for shrimp processed at the plant in Bapatla (Unit II). This seems to indicate that Choice Canning staff were aware that the company's shrimp was being sold from the Bapatla factory.

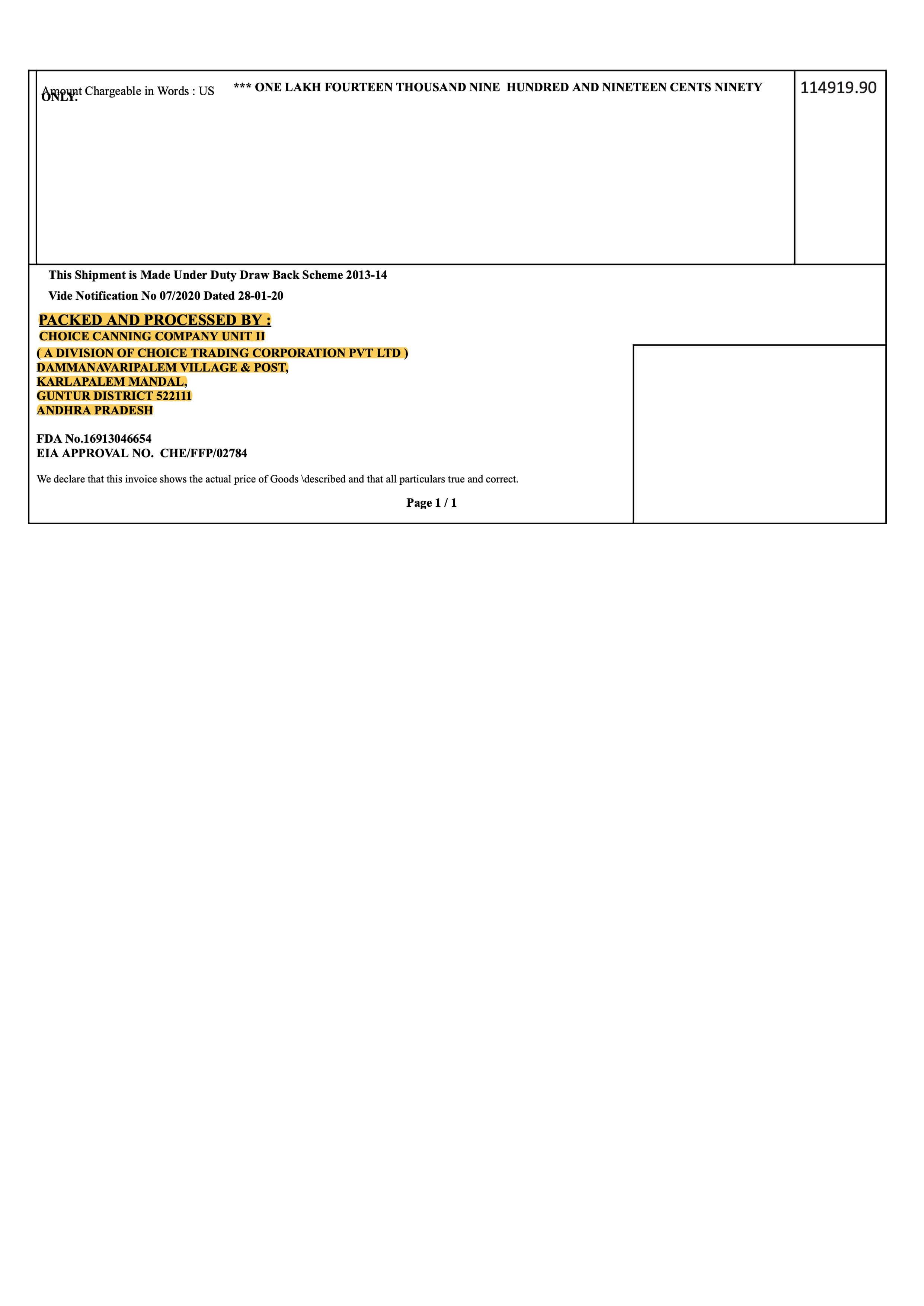

An invoice dated Nov. 16, 2023, and attached to the November email exchange, lists 15,890 kilograms of shrimp “packed and processed” by “Choice Canning Company Unit II,” the Bapatla plant (Unit II) in Dhamanavaripalem Village. This seems to indicate that shrimp was prepared at the Bapatla plant for customers in November, two months later than when the company said it stopped using the plant.

In an email sent on Nov. 27, 2023, a Choice Canning staff member shared with other managers a spreadsheet tracking production for Nov. 23 to Nov. 26. The spreadsheet lists 40,707 kilograms of shrimp packaged for shipping at the Bapatla factory (Unit II). (“Repack output quantity” means the amount of frozen shrimp in cold storage at the Bapatla plant that was being packaged for sale, according to whistleblower Joshua Farinella.). This seems to indicate that Choice Canning had shrimp at the Bapatla plant in November.

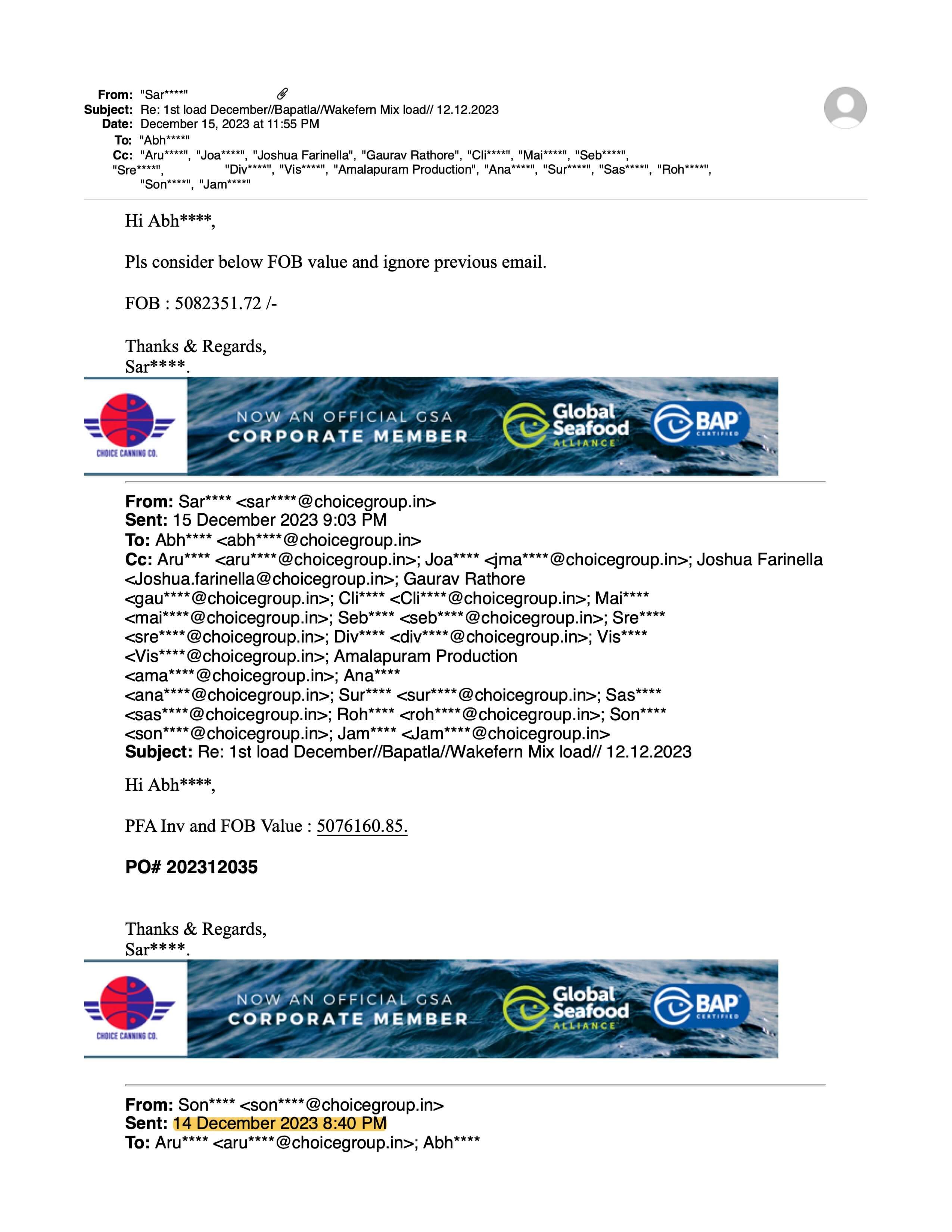

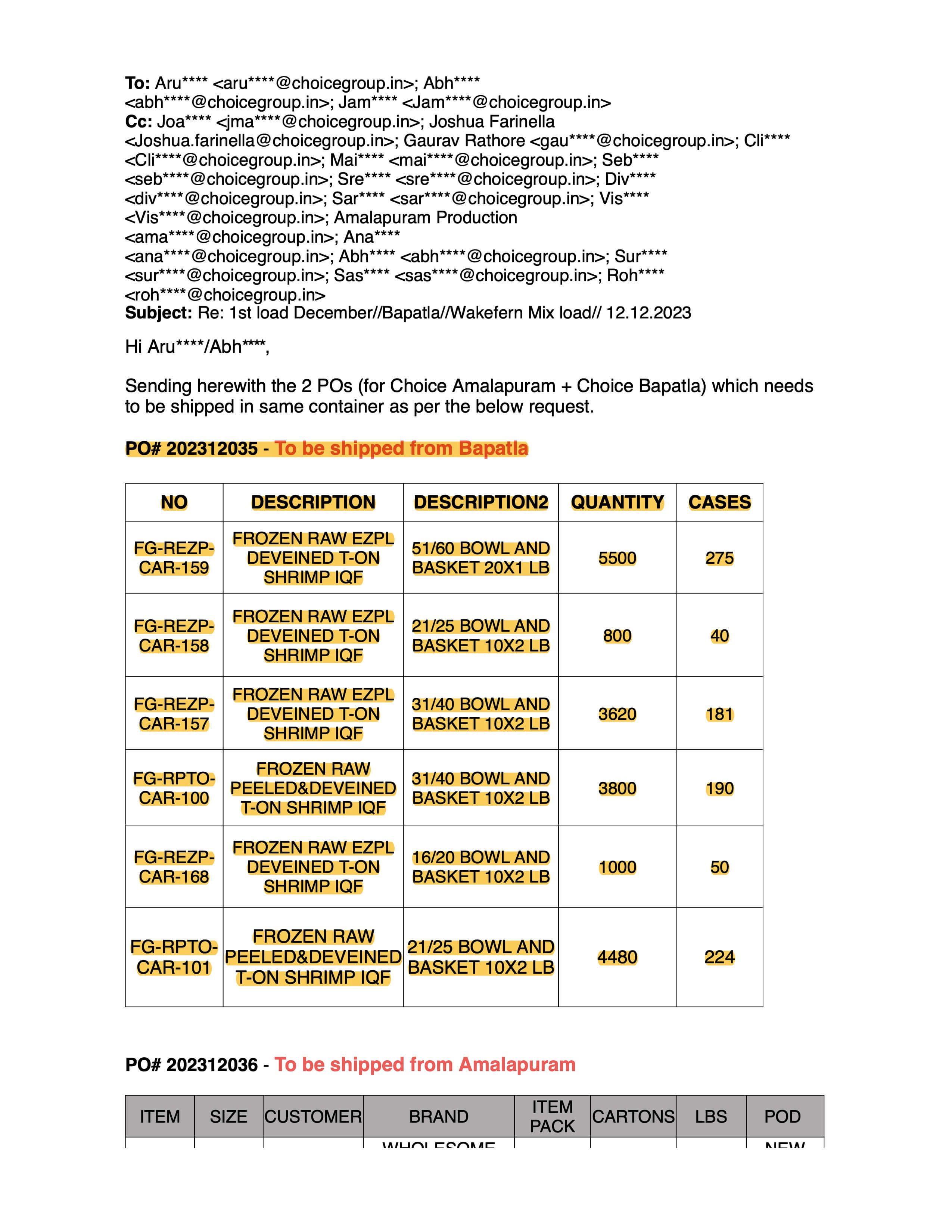

In an email sent between Choice Canning managers on Dec. 12, 2023, a staff member shared a purchase order for shrimp “to be shipped from Bapatla.” An invoice was attached. This seems to indicate that Choice Canning managers were aware of pending purchase orders that were to be filled with shrimp from the Bapatla plant (Unit II) up until at least December, three months later than when the company recently said it stopped using this plant.

An invoice dated Dec. 15, 2023, and attached to the December email exchange lists 8,716 kilograms of shrimp “processed and packed” by “Choice Canning Company Unit II,” which is the Bapatla plant in Dhamanavaripalem Village. This seems to indicate that shrimp was prepared at the Bapatla plant (Unit II) for customers in December, which does not seem to correspond with what Choice Canning recently told reporters in coverage tied to the FDA stopping an antibiotics-laced batch from this plant.

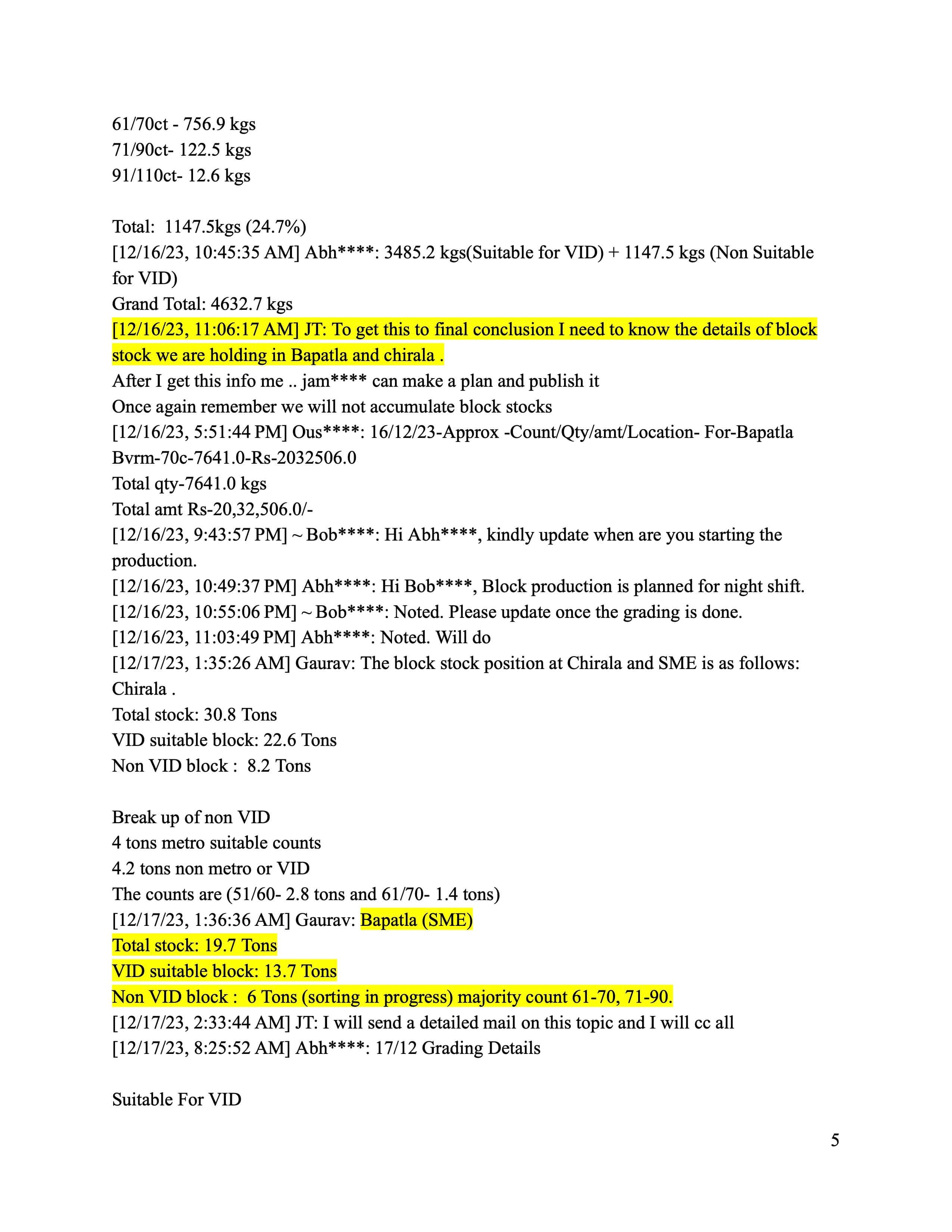

In WhatsApp messages between senior employees on Dec. 16 and Dec. 17, 2023, Choice Canning CEO JT asked how much “VID” shrimp the company had at its plant in Bapatla (Unit II). COO Gaurav Rathore reported the factory’s current stock. (VID stands for Value Innovation Division, a production unit processing breaded shrimp items.) This seems to indicate that Choice Canning had shrimp at the Bapatla plant in December, several months after when the company says it stopped using the factory.

In a WhatsApp exchange on January 9, 2024, Choice Canning’s procurement manager wrote that they had “diverted” material from the Bapatla plant (Unit II) to Amalapuram. This seems to indicate that Choice Canning was still using the Bapatla plant after September 2023.

FDA refusals of shrimp from Choice Canning, 2014 to 2023

In a letter sent to reporters on March 17, 2024, a lawyer for Choice Canning wrote that the company had never had a shrimp shipment rejected “based on an FDA inspection or otherwise showing that Choice had shipped antibiotic positive shrimp to the United States.”

(See the full letter from Choice Canning here.)A spreadsheet of Choice Canning imports rejected by the U.S. Food and Drug Administration (FDA), from 2014 to 2023, for reasons including the presence of salmonella (9) and filth (249). Information pulled from the FDA website.

U.S. Food and Drug Administration (FDA) import refusal codes, from the FDA website.

How much non-BAP shrimp goes to the plant?

In a letter sent to reporters on March 17, 2024, a lawyer for Choice Canning wrote that the company sources its shrimp from 20 farms certified by Best Aquaculture Practices (BAP). In a later section, the letter said that Choice has also processed raw material from non-BAP certified farms in off-site peeling sheds that it used for a brief period of time.

(See the full letter from Choice Canning here.)Internal company documents seem to indicate that Choice was sourcing a large quantity of its shrimp from uncertified farms. Farinella said that when he worked at the plant, there seemed to be far more shrimp coming from uncertified farms than could possibly be going exclusively to non-BAP customers. The documents below show the list of official BAP farms that Choice says it uses to supply its shrimp, in addition to invoices from purchases of raw material from uncertified farms.

A list of BAP approved “producers” to Choice Canning from the BAP certification website.

A collection of Choice Canning purchase invoices for shrimp farmers in January and February 2024 that seem to indicate that thousands of pounds of shrimp is being delivered to the plant from farms that are not named in the approved BAP list.

A spreadsheet of payments sent from the Amalapuram processing plant to shrimp farmers between January 1, 2023 and February 9, 2024. The document seems to indicate the plant was purchasing large volumes of shrimp from suppliers that were not on the list of BAP-approved producers on the BAP certification website.

Where does rejected Choice Canning shrimp go?

In a letter sent to reporters in March 2024, legal counsel for Choice Canning wrote that when shrimp tested positive for antibiotics under LCMSMS testing, the plant either sold the shrimp for use as shell waste, destroyed it or sent it back to the supplier from whom they sourced it.

(See the full letter from Choice Canning here.)This dialogue from March 2024 is between Joshua Farinella and Basava Sankar, who is affiliated with Khevana Lakshmi Santoshi Biotech. Farinella said this company is the sole firm that takes any and all shrimp waste from the Amalapuram plant. When the Amalapuram plant discovers a batch of antibiotic-positive shrimp, the company said in its letter that it sometimes sells that shrimp as shell waste. Farinella said that if shrimp was ever to be sent for waste it would never be peeled first, because there would be no point in spending the money for workers to peel the shrimp since it was due to be disposed. Such shrimp would only ever be sent as “whole shrimp”, he said. When Farinella asked Sankar if he had ever received “whole shrimp” from the Amalapuram plant, Sankar said no.

These ledgers record the daily loads of waste removed from the Amalapuram plant by waste contractor Khevana Lakshmi Santoshi Biotech from December 2023 through February 2024.

Where to redirect smelly or discolored shrimp?

Does Choice Canning uphold the highest product quality standards?

In a December 2023 email to Amalapuram plant production staff, a factory employee alerted the group that undercooked shrimp had been found in a package for Metro, a major Canadian retailer. The employee said the problem had been caught only after the shrimp had already been packed, and that it would be “reprocessed” for Dollar General, an American retail chain.

In emails spanning October and November 2023, Choice Canning CEO JT and other Amalapuram factory managers discussed a plan to send shrimp that had been rejected by the company’s quality assurance department to a South African company called Neptune. The emails mention that a representative for Neptune had inspected the shrimp and accepted it. Joshua Farinella, the whistleblower, said the shrimp would have been discolored or had other visible issues but Neptune was aware of the products’ defects before shipping.

In an October 2023 email to Amalapuram plant staff, Choice Canning CEO JT approved a plan to sell discolored, smelly and “non-exportable” shrimp to local buyers in order to free up space in the company’s cold storage facilities.

Choice Canning’s use of off-site peeling sheds

In a letter sent to reporters on March 11, 2024, a lawyer for Choice Canning said that it never processed BAP-certified shrimp in a contractor’s off-site peeling shed, which was only used for a brief period of time between January and February 2024.

(See the full letter from Choice Canning here.)An email exchange from November 2023 between Choice Canning CEO JT and Joshua Farinella touches on shrimp sent to an external peeling shed. This is outside of the date range within which the company said it used an offsite shed.

Internal reports, emails, and WhatsApp messages describe Choice Canning using off-site peeling sheds to process shrimp that was later packaged for a customer, HelloFresh, that Joshua Farinella said is supposed to only receive products certified by Best Aquaculture Practices, an organization that forbids the use of off-site sheds. HelloFresh says that 95 percent of the seafood it purchases globally is certified.

A plant production manager reports in a WhatsApp thread with other staff the quantity of shrimp sent to an external peeling shed.

In response to that message, another plant manager sent a photo of a product reporting sheet indicating that shrimp lot 1947 was part of the raw material that was sent to the external peeling shed (“external ppc”).

Daily production report appearing to confirm that shrimp from lot 1947 was used for HelloFresh

Photo of HelloFresh packaging featuring the BAP certification mark

Press release announcing that BAP does not allow the use of external peeling sheds

In a letter sent to reporters on March 17, 2024, a lawyer for Choice Canning said the shrimp that goes to an offsite peeling shed is not “owned nor sold by Choice,” and that Joshua Farinella had previously said that sanitation in the shed was “satisfactory.”

(See the full letter from Choice Canning here.)In a February 2024 email, an Amalapuram plant manager alerted other staff of a report from the quality control department that there was no ice on peeling tables at an offsite shed that supplies the plant. The manager said a lack of ice can lead to “discolouration, deterioration, and decomposition (smell)” in the shrimp.

This January 2024 email from Gaurav Rathore, COO, about selling shell waste from the external peeling sheds, seems to indicate another clear financial relationship between the sheds and the Amalapuram plant.

In a January 2024 email to Amalapuram plant leadership, a pre-processing manager alerted the others that there was “irresponsibility” and “no supervision” at the external peeling shed, that “all the peeling tables were without ice” and that “associates were working without a mask or head cap.”

Worker tallies and announced or unannounced audits

The report produced following an October 2023 audit by Best Aquaculture Practices (BAP) of the Amalapuram plant found that on the days of the audit, October 4 to October 6, there were zero local workers on site and 250 migrant workers.

An internal spreadsheet emailed to Joshua Farinella each morning by a human resources manager totaled the number of local workers who arrived at the Amalapuram plant for shifts each day, broken down by the labor contractor who had provided them. This spreadsheet does not include headcounts for the migrant workers who lived onsite. The spreadsheet seems to show worker numbers higher than what was reported on the BAP audit. (The dates on this spreadsheet are presented in day/month/year format.)

The report produced following a November 2023 audit by BRCGS of the Amalapuram plant said that on the days of the audit, November 2 and November 3, there were 350 workers onsite, with no distinction between local and migrant labor.

An internal spreadsheet emailed to Joshua Farinella each morning by a human resources manager totaled the number of local workers who arrived at the Amalapuram plant for shifts each day, broken down by the labor contractor who had provided them. This spreadsheet does not include headcounts for the migrant workers who lived onsite. The spreadsheet seems to show worker numbers higher than what was reported on the BRCGS audit. (The dates on this spreadsheet are presented in day/month/year format.)

A report from Best Aquaculture Practices produced after an audit that the organization described as “unannounced” at the Amalapuram plant from October 4 to October 6, 2023.

A WhatsApp thread where Choice Canning’s COO sent a message about the audit on October 4, 2023, at 7:36 a.m. Joshua Farinella, the whistleblower, said that auditors never showed up at the plant before noon.

Labor contractor invoice and wage concerns

In December 2023, Choice Canning managers and Joshua Farinella discussed a wage increase for some of the workers at the Amalapuram plant to the legal required minimum wage. JT, the CEO of Choice Canning, wrote in an email that he was “shocked” that these workers were not already paid this amount. The company’s vice president of human resources Vid**** said that this issue had been raised before with the CEO.

A January 2024 invoice from a contractor that provides migrant labor to the plant listed the basic salaries for 95 employees.

This document shows minimum wage requirements for seafood workers in Andhra Pradesh between October 2023 and March 2024

An October 2023 invoice from a different contractor that provided workers to the plant seemed to show deductions for “mess” charges.

In a letter sent to reporters on March 11, 2024, a lawyer for Choice Canning said there was only one incident of a labor contractor failing to pay wages on time which had been resolved, and there had been no issues with workers being paid on time since then.

(See the full letter from Choice Canning here.)Some of the workers at the plant voiced broad frustration about delayed payments. In December 2023, a plant engineer wrote to human resources that four other engineers had not shown up to work because of delayed paychecks. A few days later, the human resources executive said the wages had been paid and offered an explanation for the delay.

In a January 2024 email, a human resources executive at the Amalapuram plant wrote to other managers to alert them that workers had filed a complaint with local police about a labor contractor named Ram****, who the workers said had not been paying them and had been abusing them when they asked about their wages.

In a November 2023 email to other managers, a human resources executive at the plant described a different incident with a different labor contractor involved in late payments. He said he was “consistently receiving complaints” about this contractor.

A January 2024 invoice from the labor contractor Three Seasons seemed to indicate that three of the workers had worked over 360 days in one year. Farinella said this contractor provided engineers to the plant.

Concerns about living conditions at the plant

In a January 2024 WhatsApp message, a member of the Amalapuram plant staff texted Joshua Farinella, the whistleblower, a photo of a worm discovered in food served to workers.

The next day, workers in a WhatsApp group chat for plant staff managing the canteen discussed what to feed workers following the discovery of the worm. Farinella said he wanted the entire kitchen cleaned and fumigated, and that he was willing to pay for it out of his own pocket if necessary.

In a December 2023 email, an Amalapuram plant manager notified others of a bed bug outbreak affecting more than 500 cots.

In an October 2023 email to Amalapuram plant managers, the factory’s vice president of human resources expressed immediate need for more bunk beds in the dormitories.

In a December 2023 email exchange to Amalapuram factory managers, a welfare officer alerted the others that the plant needed to purchase more mattresses, bed sheets and pillows because workers were sleeping on bare metal cots.

In a November 2023 email exchange, plant managers discussed how to solve a labor shortage. An executive from the human resources department cited a lack of space in the dormitories as a reason for the shortage.

During a recorded conversation with Joshua Farinella in January 2024, a welfare officer at the Amalapuram plant said the company stopped providing sanitary napkins to workers because they were taking the supplies home.

In a December 2023 email, a welfare officer at the Amalapuram plant alerted senior management that one of the men’s dormitories did not have air conditioning or fans.

The company voices confidence in Joshua Farinella

Emails and transcripts of conversations with Choice Canning’s senior management, including its CEO Jose Thomas (JT), between November 5, 2023, and February 6, 2024, seem to show officials expressing trust in Joshua Farinella.

DownloadTranscript of February 6, 2024, meeting between Joshua Farinella, CEO JT, Vice President of Sales and Procurement Jacob Jose, and Director Thomas Jose

Email from CEO JT on November 5, 2023, to plant managers saying Farinella has the full support of JT and the company’s shareholders