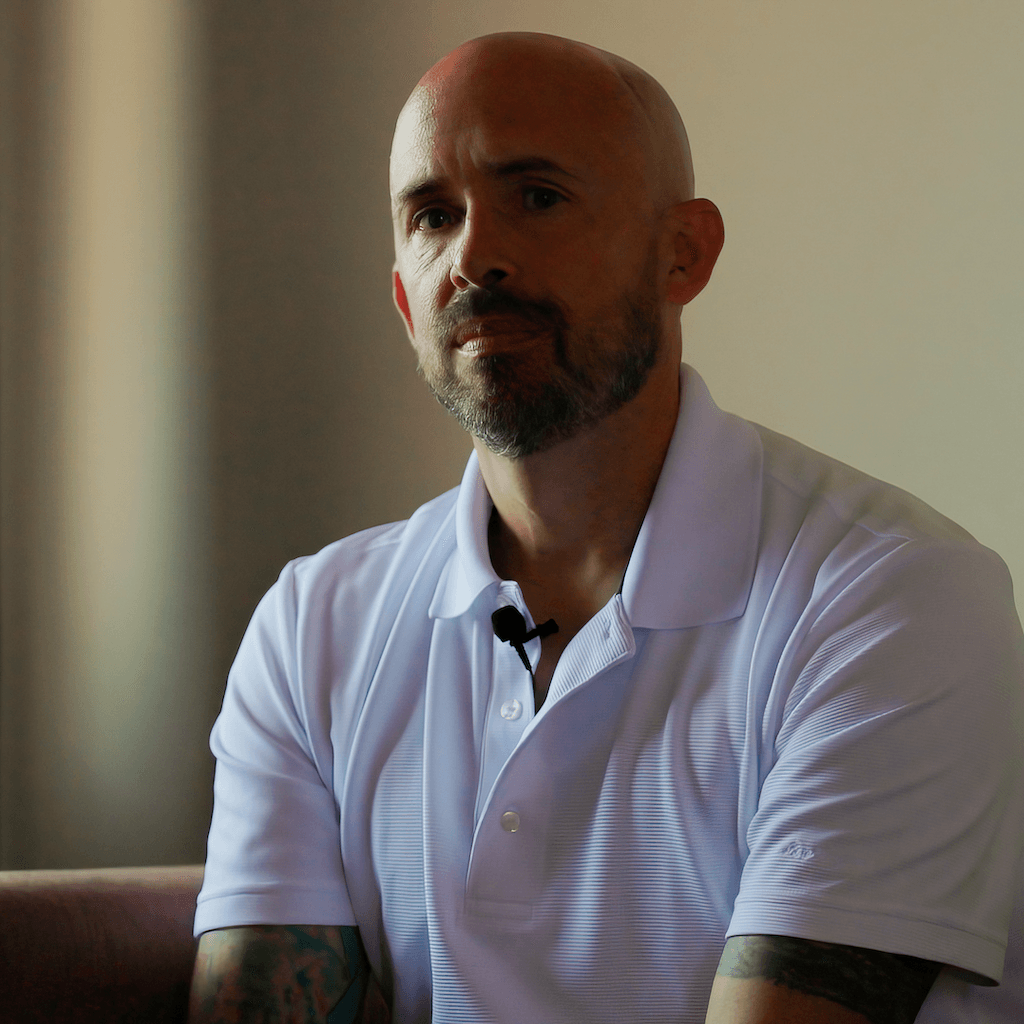

On October 29 2023, a 45-year-old American named Joshua Farinella flew into the city of Amalapuram near India’s eastern coast to start his new job as the general manager at a shrimp processing plant. Farinella, who is softly spoken with a shaved head, neatly trimmed beard and full sleeve of tattoos, was excited about the prospect of living abroad for the first time. True, this would be a high-pressure job, and he would miss Christa, his wife, but he had negotiated a salary of $300,000 a year, more than double what he’d earned at another seafood company in the United States. He joked that he was now the best paid shrimp worker who did not own his own company. He figured that if he could stick it out for two or three years he would be set up for life: he looked forward to upgrading his camper van, paying off his car loan and setting aside some money for his stepdaughter’s university education.

Surrounded by a seven-foot-high concrete wall, the plant was about six miles northeast of Amalapuram, and was surrounded by rice paddies and coconut trees. Security guards patrolled the perimeter, not an uncommon sight at facilities like these. Inside was an eight-acre compound where shrimp, cultivated in nearby ponds, were beheaded, deveined, treated with chemicals that keep them moist, and shipped abroad. In 2023 alone, the plant, leased by a company called Choice Canning, filled frozen food sections at stores such as Walmart, Price Chopper, ShopRite and Hannaford with a little over 19 million pounds of packaged shrimp. (Walmart and Ahold Delhaize, Hannaford’s parent company, said they were looking into the allegations. ShopRite and Price Chopper did not respond to requests for comment.)

When he arrived at work, Farinella was struck by the number of workers streaming through the gate. It reminded him of an airport terminal, though there always seemed to be more people arriving than leaving. In the days that followed, he came to realise how much labor was required to process shrimp in the quantities demanded by head office – a quota of 40 shipping containers or over 600 tons each month. On any given day, there might be more than 650 workers at the plant, typically hired by third-party contractors. Hundreds of the workers lived locally in Andhra Pradesh and they went home at the end of each day. The rest were migrant workers who lived at the plant and they served as the backbone of the operation. The plant ran day and night, racing against the heat which constantly presented the threat of spoiling. The migrant workers were mostly women, almost exclusively recruited from impoverished corners of the country such as West Bengal. Many came from the lowest social caste and were illiterate. They slept in spartan dormitories on-site in metal bunk beds. A security guard was usually posted outside near the building’s front door.

At 3 a.m. on November 11, 2023, Farinella was woken up at his apartment, which was a short drive from the plant. A manager had sent a WhatsApp message informing him that a woman had been found running through the plant’s water treatment facility at 2:30 a.m. “She was searching for a way out of here,” the manager wrote matter-of-factly. “Her contractor is not allowing her to go home.” (Later, another manager would explain in a recorded conversation that workers used to escape over the concrete wall, but this had now been fixed “so no one can go out.”). The woman made it as far as the main gate, but was turned back by guards.

Forbidding workers to leave their plants when they choose to is a violation of the Indian constitution and also likely violates the country’s penal code, according to the Corporate Accountability Lab, an advocacy and research group. In a recorded conversation, a manager had explained to Farinella that some employees at the plant were allowed out twice a week to shop at the market. There shouldn’t be any reason for them to attempt an escape in the dead of night, Farinella figured. Arriving at the plant several hours later, he tried to get an answer about what had been going on. He was told by a Human Resources manager that it had all been a misunderstanding. The woman hadn’t wanted to leave after all. An alarm bell went off in Farinella’s mind.

Farinella had worked in the food industry since 2015. Choice Canning made frozen meals in his hometown and had given him a job as a quality-assurance officer in 2015 overseeing food safety rules. He then worked for another seafood company, Lund’s Fisheries, ensuring its supply chain complied with regulations, before returning to his old firm in 2023. He was used to gaps in accounting and flaws in audits. But this seemed much more serious. Farinella, who was raised in a former mining town in Pennsylvania by a Vietnam veteran and a social security worker, had gone off the rails as a young man, living on the street temporarily and picking up convictions including for drunk driving and trying to cash false cheques. He has since distanced himself from his family; he stopped talking to his parents after they disapproved of him marrying a black woman.

At the plant in India, he would find himself covering up overcrowding on the site by making plans to hide workers when inspectors came around. He found himself misleading customers about the provenance and quality of their shrimp, including its certification status or farm origin, and he said he was told to send off consignments of tainted shrimp to America. Managers who worked for Choice Canning could be frustratingly evasive, he added, but, at times, they could also be startlingly candid. He captured his dealings with them in secret recordings, screenshots and thousands of pages of documents.

“I have been fighting this from afar for years,” he said, referring to his time in food safety and quality assurance. “Then I find myself right in the middle of it. Not just in the middle of it but it was literally my job to make all of the fucked up things keep happening.”

Americans devour, on average, nearly six pounds of shrimp a year, an amount that has doubled in a generation. In 2001, the crustaceans cost around $12 per pound, when average prices peaked, and were regarded as a delicacy. Since then, restaurants and supermarkets have begun to source them overseas and the prices have plummeted. Today, some seafood restaurants offer an “ultimate unlimited shrimp deal” for $25.

In 2015 the hidden costs of cheap prawns were revealed. Reporters found trafficked Burmese migrants, most of them women, held in slave-like conditions in shrimp peeling sheds in Thailand, a country that for much of the prior decade had been the preferred supplier for major Western supermarkets. Some of these food companies cut ties and imports from Thailand dropped.

India helped fill the void, with help from its government which supplied subsidies and loosened laws restricting foreign investment. By 2021, India exported more than $5 billion of shrimp globally and was responsible for nearly a quarter of the world’s shrimp exports. About one in three of the shrimps consumed by Americans today comes from India.

Choice Canning is one of the largest Indian suppliers in the market. It has corporate offices in two big Indian cities, Kochi and Chennai, as well as in Jersey City, N.J., and sent shrimp worth more than $80 million to America in 2023.

In November 2022, the company announced it would be the first Indian company to become a corporate member of the Global Seafood Alliance (GSA), an industry body that promotes responsible practices. Choice Canning sought certification by the Alliance’s monitoring outfit, Best Aquaculture Practices (BAP), which offers to certify every stage of a seafood supplier’s production line. The workplace in Amalapuram carries the stamp of BAP approval. Choice Canning said that shrimp farms that they use do as well. (Presented the findings, the Global Seafood Alliance said they take them seriously and will investigate if they find evidence of violations BAP.)

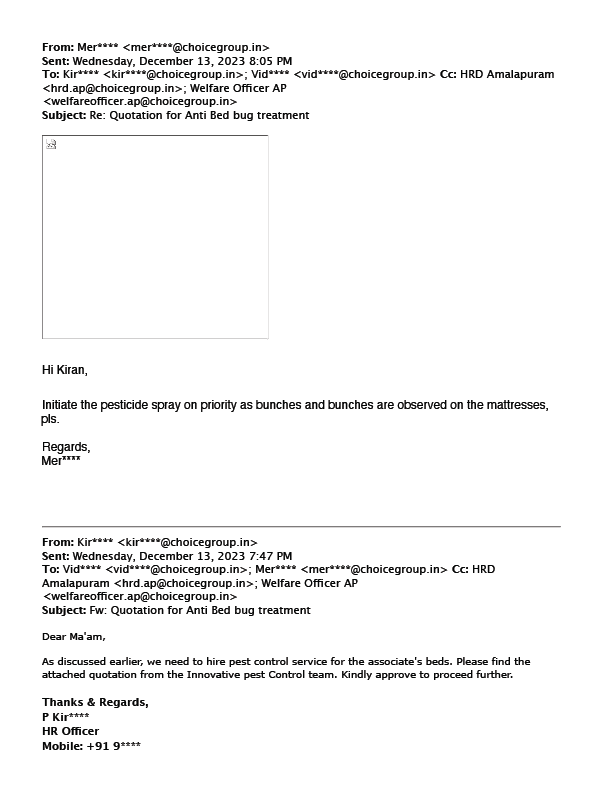

Farinella said he was confused to find that when the plant tested for antibiotics in the shrimp, these tests came back positive more often than he had expected. In the U.S., the Food and Drug Administration (FDA) bans the use of pharmaceuticals in shrimp. (The FDA did not respond to a request for comment.)

Much of the shrimp that India produces are raised at small aquaculture farms. Sometimes such farms rely on antibiotics to protect the shrimp from pathogens.

“If just about everything we pack is BAP and the farms are BAP then how is it that the antibiotics keep coming up?” Farinella wrote to the company’s senior quality assurance manager in a WhatsApp message.

“We never buy shrimp from BAP farms,” the company’s senior quality-assurance manager replied. “All are local, unregistered farms.” The manager, in a jocular aside, told Farinella that “you can imagine the level of documentation skills” required to make it seem otherwise. He added a smiley-face emoji.

How long has this been going on, Farinella asked. “It has always been so,” the manager wrote. “India doesn't have even 10 percent of the BAP farming capacity it claims. Sad, but that's the reality!”

The Corporate Accountability Lab report suggests he is right about the extent of the problem. The report says that the Indian shrimp industry is rife with human rights, environmental and safety violations, including instances of forced labor, and that audits by BAP and similar organizations are flawed.

Choice Canning hired a firm, SGS, to conduct daily audits for internal purposes to help police hygienic conditions. These audits often detailed sanitary concerns such as the smell of decay, flies, slime, sludge, lack of ice, broken refrigerators, machines contaminated with algae and fungus, hair and black spots on shrimp, and a spitoon full of chewing tobacco on the factory floor. Annually, auditors from the same firm, SGS, also produced a public-facing audit where the plant was given a clean bill of health. (SGS said they could not share the results of their audits for confidentiality reasons but that they were conducted based on the terms they had with their client.)

Internal Daily Audits Offer A Rare Look Into The Plant’s Challenges

The captions under the photos were written by the auditors themselves.

“Ship it”, the WhatsApp message read.

This was surprising, even by the standards Farinella had come to expect at Amalapuram. His boss, Jacob Jose, the company’s vice president of sales and procurement and the son of CEO Jose Thomas, who goes by JT, had just been informed that 225 cases of raw shrimp bound for Aldi South supermarkets in the U.S. had tested positive for antibiotics.

The widespread use of antibiotics in agriculture is causing resistance to the medication needed to treat all sorts of infections to rise across the world. In 2019, the Centers for Disease Control and Prevention, an American government agency, said close to 3 million antibiotic-resistant infections occur each year in America, killing tens of thousands.

While the FDA bans importing shrimp treated with antibiotics, the agency only inspects roughly 1 percent of imported shrimp. By contrast, the EU checks 50 percent of imported shrimp from India. The chances of any one batch of contaminated shrimp from Choice Canning or other companies being stopped are low, according to researchers. A company inventory spreadsheet shows that over 250 tons of antibiotic-positive shrimp was received by Choice Canning’s Amalapuram facility in 2023. It is difficult to ascertain exactly how much of this shrimp made it to the U.S., but company documents seem to show instances when shipments made the full journey. A review of FDA data indicates that the agency has tested shrimp from Choice Canning for antibiotics just 21 times since 2003 and never found a violation. In that same period, the company sent more than 100,000 tons of shrimp to America.

Farinella said that paperwork meant to trace shrimp to certified farms and track the presence of antibiotics was sometimes misleading. The Vice President Sales & Procurement told him not to use the word “antibiotics” in any internal communications, for example. “Please use the word Oscar” to refer to shrimp that had tested positive for with antibiotics, the manager wrote to him on WhatsApp, adding “lol.” (The company denied ever shipping antibiotic-tainted shrimp to the U.S. and said that this exchange and the meaning of ‘Oscar’ have been misrepresented by Farinella.)

Farinella said that even though he disagreed with the policy, he did as he was told. “Almost 10,000 pounds of Oscar in finished packaging for Wakefern. What to do?” Farinella wrote on WhatsApp to the company’s vice president for sales on February 1, 2024. “Ship on one container,” the executive texted back. Off it went to America, packaged in bags marked “all natural.” (Wakefern did not respond to requests for comment.)

Managers Discuss Antibiotic Shrimp

(AB+ means “antibiotic positive.” CIST means “Cooked in shell, tail on.”)Joshua FarinellaPlant managerGot a load I’m putting together now for wakefern. 300 cases of CIST 31/40 for wholesome pantry are AB+. Everything else is good. Can it go?

Jacob JoseVice President of Sales & Procurement of the Choice Canning CompanyHow many items total?

Jacob JoseVice President of Sales & Procurement of the Choice Canning CompanyPlease use the word Oscar lol

Joshua FarinellaRoger. 7 items. 1 Oscar of 300 cases. 400 cases of that item to be loaded.

Jacob JoseGo ahead

Joshua FarinellaPlant managerAlmost 10000 pounds of Oscar in finished packaging. For Wakefern. What to do?

Jacob JoseVice President of Sales & Procurement of the Choice Canning CompanyIs everything else ok?

Joshua FarinellaEverything else is fine.

Jacob JoseShip on one container

Joshua FarinellaOk

(CIST means “Cooked in shell, tail on.”)Joshua FarinellaPlant managerNothing on why both didn’t have all the Aldi cist.

Jacob JoseVice President of Sales & Procurement of the Choice Canning Company?

(RTNC refers to tail-on, chemical-free raw shrimp)Joshua Farinella225 cases of Aldi rtnc are Oscar.

👍Jacob JoseShip it

The Choice Canning site is filled with large concrete buildings that house processing facilities, warehouses, freezers, dormitories, electrical equipment and offices. Clothing is hung out to dry on lines strung between buildings and mattresses are laid out in the sun to air. During his time as the plant manager, Farinella had a wide range of duties: sourcing workers and supplies of shrimp, managing finances, and making sure that plant hit its monthly production quota.

He struggled at first to establish how many workers lived on site, how they were housed and fed, and how their contracts worked. At one point he stumbled across what he called a “hidden dormitory” located above the ammonia compressors used for refrigeration, putting the workers in danger if there were a leak or a fire.

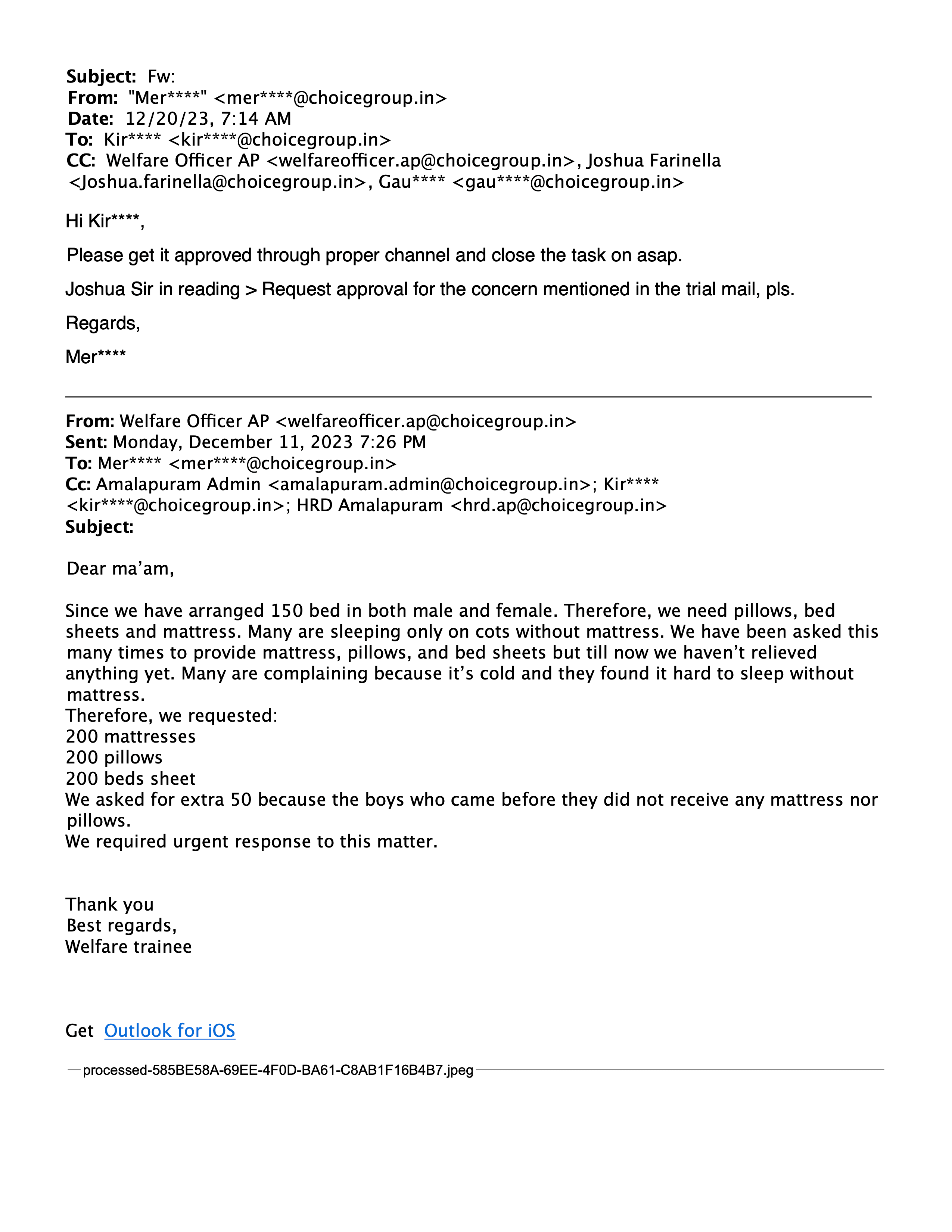

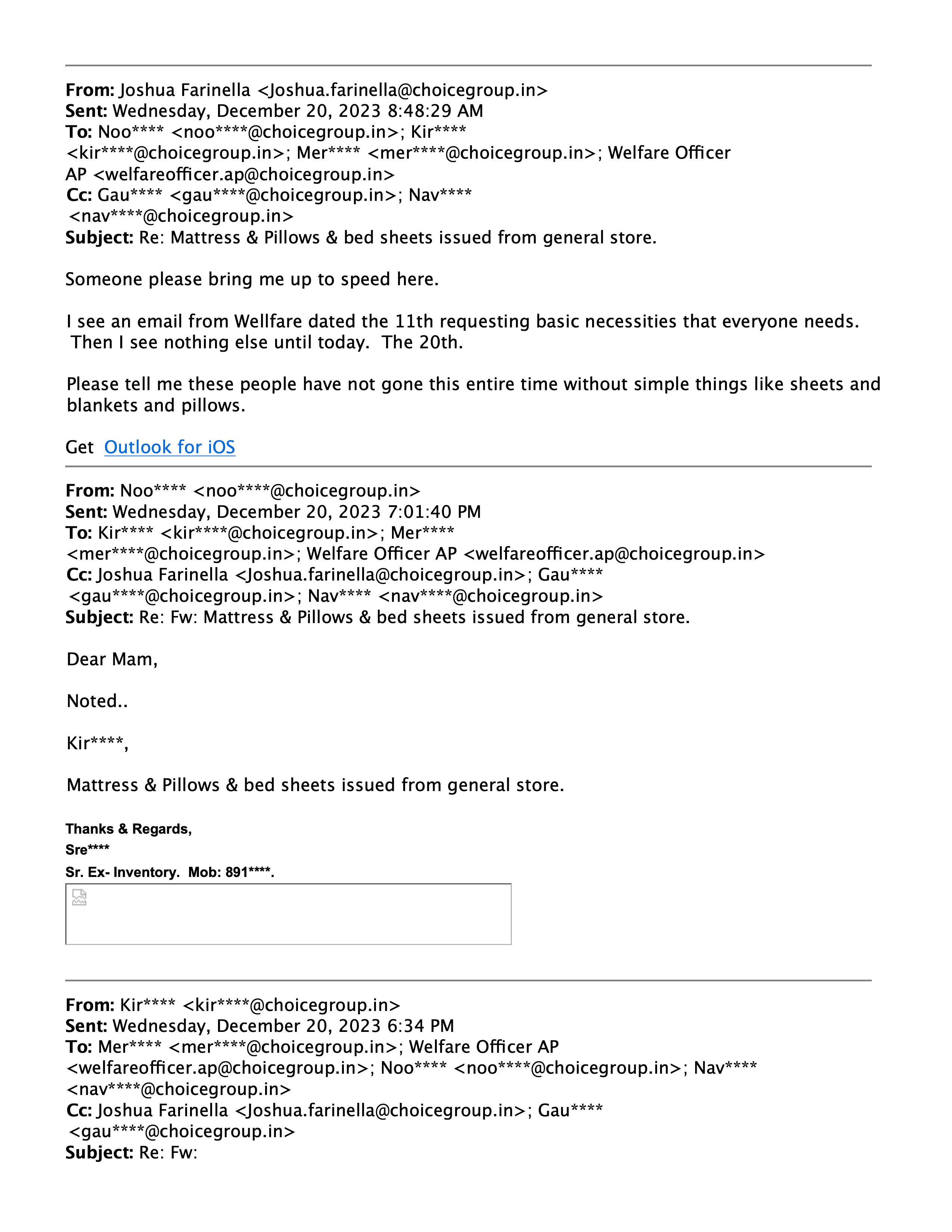

Managers at the plant knew that living conditions for workers needed improving and they conducted regular discussions on WhatsApp and email about how to fix various problems. Once a manager emailed him a photo of bedbugs – part of an infestation that colonized more than 500 mattresses. Farinella found workers sleeping on the floor, using only their shirts as pillows. But he said he and others struggled to get authorization for the necessary changes. “We need more bunk beds immediately, this cannot wait for another day please!,” the plant’s vice president of human resources wrote angrily in an email. “Existing people are facing trouble for months.”

A few weeks later Farinella discovered during a recorded conversation with a labor contractor for Choice Canning that 150 women workers had not had a day off in a year after two employees asked whether they could be released for an outing.

Farinella approved it instantly. He later said that he felt like his “hands were tied” and that he was blamed for anything that went wrong despite not being given the power to change things for the better.

It was also hard, he said, to tell how long employees spent working. A human resources executive admitted candidly in a Zoom meeting recorded by Farinella how she would need to adjust attendance records and timecards, so as to pass an audit.

State law in Andhra Pradesh stipulates that workers must be paid at least 450 rupees ($5) per day. But an invoice from a labor contractor and a separate email exchange between managers seemed to indicate that some workers were paid only 350 rupees a day. (The company has since said that it always paid the minimum wage to all of its “associates” and recently even gave a raise to some of its staff.)

“It felt dirty,” wrote Farinella later. “I didn’t even want to make eye contact with the workers who were living there or the local workers. I was disgusted and ashamed of everything. I know the workers couldn’t be OK with everything there. And I also knew that every one of them probably thought I was most of or at least part of the problem.”

In December, Farinella asked Jacob Jose if workers could be paid the minimum wage. In an email exchange with senior executives, JT declared himself “shocked” that they weren’t already. One of the executives reminded JT that he had previously told them “not to make any changes in Amalapuram for time being,” when it came to wages. (In internal emails, company managers later said they planned to raise the wages.)

Too Few Cots, Vermin, Permission To Leave

%20--%20Reg%2C-732.png)

We need more bunk beds immediately, this cannot wait for another day please! Existing people are facing trouble for months and there is a delayed requirement to sources more associates. Unless we get the bunk beds, nothing can move forward.

We need pillows, bed sheets and mattress. Many are sleeping only on cots without mattress. We have been asked this many times to provide mattress, pillows, and bed sheets but till now we haven’t relieved anything yet. Many are complaining because it’s cold and they found it hard to sleep without mattress. Therefore, we requested: 200 mattresses 200 pillows 200 beds sheet We asked for extra 50 because the boys who came before they did not receive any mattress nor pillows. We required urgent response to this matter.

Someone please bring me up to speed here. I see an email from Wellfare dated the 11th requesting basic necessities that everyone needs. Then I see nothing else until today. The 20th. Please tell me these people have not gone this entire time without simple things like sheets and blankets and pillows.

Initiate the pesticide spray on priority as bunches and bunches are observed on the mattresses, pls.

We have 558 beds on the factory accommodation side which need bed bug treatment. It costs nearly 40,000. Please find below trail mail and kindly Approval it to do the needful.

The curfew time is 10:30 PM. After this no Resident Employee/Guest is permitted to go out from the Housing Facility unless they have the permission from the Factory Head / Administration Manager.

In January 2024, inspectors from Aldi South, a global supermarket chain, were due to visit Amalapuram to conduct a social audit checking labor conditions at the plant. While some audits are unannounced, Aldi South’s audit was scheduled months in advance. (Aldi South said it was “taking the allegations seriously” and would need more time to investigate.) Farinella met other supervisors to discuss preparations and recorded the conversation. Managers focused on what to tell auditors with regard to the number of workers at the plant. The size of the workforce is of particular concern during audits, according to the Corporate Accountability Lab report, because auditors want to check the tally of employees at a facility against wage records, available beds, and amount of workspace on the factory floor to see if there are any concerns related to underpayment or safety.

The managers also discussed a plan to move the workers offsite to a rented location nearby before the auditors arrived. Labor researchers say that this is not an uncommon practice in dealing with auditors. “We need to show a sizable number to them,” mused the quality-assurance officer during a recorded meeting in deciding what might be a convincing statistic to tell auditors. Eventually, the managers opted for 415 as a number that would seem plausible.

A few days later, in a recorded meeting, Farinella discussed the plans with a different human-resources executive.

“So basically we’ll call them when the auditor comes in, we'll call them and say ‘go run away and do something else for the day,’” he said.

“Yes,” said the executive.

“How the hell did you come up with that idea?”

“Sir, JT is keeping a knife on my neck. Ideas will come.”

Discussion Of Food Safety

(BAP is a certification scheme run by the Global Seafood Alliance that sets various traceability and labor requirements such as prohibition of forced labor.)Joshua FarinellaPlant managerHi! Saw the antibiotic email. Have a question. If just about everything we pack is BAP and the farms are BAP then how is it that the antibiotics keep coming up?

Sre****Quality Assurance ManagerHi Josh. I may sound strange. We declare them as BAP 4 star or 3 star, but not bought from BAP farms. Star is only in documents.

Sre****Quality Assurance ManagerWe never buy shrimp from BAP farms.

Joshua FarinellaOh ok. I get it now.

Sre****All are local, unregistered farms. You can imagine the level of documentation skills QA possess to bring them to BAP compliance 😀

Soon after he arrived, Farinella had discovered another concern: off-site peeling sheds. One was a 35-minute drive from the main production facility, the other an hour and a half away. BAP and other certifications forbid the use of off-site peeling sheds because they are tougher to regulate. The CAL report says that “peeling sheds are often hidden and rarely audited.” The two sheds that Choice Canning used processed 10,000 to 15,000 pounds of shrimp per day – roughly half the quantity that the company shipped to America, according to Farinella and from dozens of daily production reports. (The company has since said that none of the shrimp processed in these sheds was for BAP customers. It did not specify where this shrimp was sold.)

Throughout his time at the plant, Farinella received a relentless stream of messages from the senior leadership. JT, the chief executive, often seemed incensed at hygiene shortcomings. “Get this cold store mess solved at the earliest,” he wrote in a WhatsApp message. “Whoever did this will suffer in life!”. One day, after being shown a photo of the site in good order, he said that he had just been told that $80,000 worth of his produce had to be thrown away because American customers complained about the smell. “How do I believe your photos?” he wrote on WhatsApp to his staff on-site. But Farinella also felt stonewalled when he tried to make improvements. “When I would tell JT what changes I needed to make I would be flat out told ‘no’.”

Farinella was also under constant pressure for not generating enough revenue. In a recorded Zoom meeting on February 6, 2024, between Farinella and three executives, including JT, the leaders expressed frustration with Farinella for being insufficiently productive, using what Farinella described as the “usual veiled threat of firing.” “I don’t know what your January results are,” said JT. “You should be more concerned than I am.”

In January, Farinella finally decided to go public with what he knew about the plant and contacted a journalist. “I think it is likely that I was hired not to manage the facility, but to be the American face that provides the appearance of legitimacy,” he said. For a plant with so many problems, he added, “I’m afraid I can’t be that face.”

A videographer travelled to India to document conditions at the plant. Farinella was so on edge that when he saw armed police near his apartment building he felt his heart was almost “jumping out” of his chest. (It turned out to be a coincidence.)

A few days later Farinella caught a plane back to America and emailed his notice from the airport. After landing in Pennsylvania, he stopped by McDonald’s on his way home from the airport. “I don’t even like McDonald’s,” Farinella said. “But that was a damn good cheeseburger that day.”

Pressure was starting to wear on Farinella’s colleagues, too. On February 14, 2024, a human resources officer from the plant contacted Farinella on WhatsApp to say that he, too, was quitting Choice Canning. The hours were ruining his marriage, he said, and the dispute with local workers over wages had wrecked his reputation. He was being threatened on the phone. “While I was going home in my car,” he later wrote in WhatsApp to Farinella, “some of the local people attacked me with stones.”

Farinella retained a lawyer in America and filed a formal whistleblower complaint to the FDA and several other federal agencies. He wasn’t sure what good it might do, but he wanted to state what he had seen on the record.

The same day, Aldi South’s auditors arrived to Amalapuram. They were there to conduct the inspections that the local managers had been discussing for weeks. After the audit was finished that evening, Farinella contacted his former colleagues and asked whether they had gone ahead and relocated workers during the audit. Two of the managers confirmed that they had indeed. “Exactly sir,” one wrote in WhatApp. “All workers are sent outside.”